What is Net Zero Carbon all about?

Net Zero carbon means achieving an overall balance between emissions produced and emissions taken out of the atmosphere. According to the Intergovernmental Panel on Climate Change (IPCC), limiting global temperature warming to 1.5°C will require global net human-generated CO2 emissions to decline by about 45% from 2010 levels by 2030, reaching Net Zero around 2050.[1]

The Carbon Trust has helpfully set out what this means for organisations:

‘A net zero organisation will set and pursue an ambitious 1.5°C aligned science-based target for its full value-chain emissions. Any remaining hard-to-decarbonise emissions can be compensated using certified greenhouse gas removal.’[2]

This means that suppliers to those who have committed to Net Zero Carbon will also need to be Net Zero Carbon, including those providing buildings and fit-outs.

It is heartening that globally over 5,200 companies of all sizes have signed up to the UN Race to Zero campaign. This includes almost two thirds of FTSE100 companies. Large UK firms participating in Race to Zero have a combined annual turnover of £700B and buy from hundreds of thousands of smaller companies who will all have to move to Net Zero.

Science-based targets and Net Zero Standards to Achieve Net Zero

To enable companies to align their near- and long-term climate actions with limiting global warming to 1.5°C, in October 2021 the Science Based Targets Initiative (SBTi) launched the Net Zero Corporate Standard, providing a credible and independent assessment of corporate progress.

SBTi’s standard requires a 50% emissions reduction before 2030 and 90 to 95% before 2050 to achieve the 1.5°C limit. And the remaining 5 to 10% hard-to-decarbonise emissions will need to be removed from the atmosphere.

This means that carbon offsetting is limited to 5 to 10% of baseline emissions.

Net Zero Carbon buildings

Buildings (and their contents) are a logical place for organisations to start tackling carbon emissions because they:

- Reflect an organisation’s culture and values

- Set an example for staff

- Are where visitors, customers and potential recruits see the organisation for the first time

- Are currently undergoing change as a result of COVID-19 and increased home working

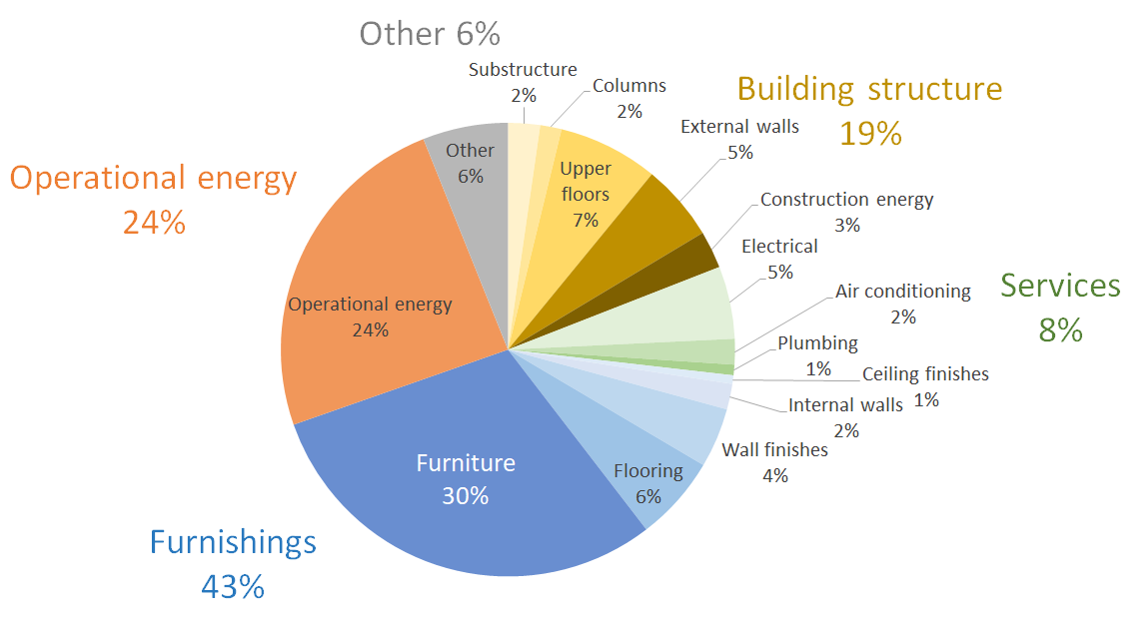

Tackling building-related emissions starts with understanding what the major sources of emissions are. Figure 1 shows the total greenhouse gas emissions of a commercial building over a 40-year life.

Figure 1: Greenhouse Gas Emissions over the 40 Year Life of a Commercial Building[3]

Fit out churn is one of the most significant sources of carbon emissions in a building’s lifetime. The largest contribution of all is furniture, driven by carbon intensive manufacture and an average lifetime of around 6 years, at which time it is mostly replaced by more furniture from virgin resources.

This means that substantial savings can be made when fitting out or refurbishing an office.

Historically, carbon emission reduction efforts have focussed on Operational Emissions – which are those created by the use of energy.

But as Figure 1 shows, Embodied Emissions – the emissions that go into making materials and products – are far greater than Operational over the lifetime of a building.

How to reduce building carbon emissions

Embodied emissions are addressed in two ways:

Circular Economy

Remanufacturing returns items to as-new condition with no difference in appearance or performance compared to the same items made from virgin materials.

This saves 80% of their greenhouse gas emissions and saves money because the remanufactured items are lower cost (and also create local jobs).

Recycling is another circular economy option, but is more emissions-intensive because it requires breaking items into their constituent materials and then reprocessing them before recombining them. In buildings, recycling has historically occurred for structural concrete and steel.

Carbon Negative Materials

Carbon negative materials have the net effect of removing carbon dioxide from the atmosphere rather than adding it. Examples are emerging from a range of sectors:

Interface has developed a range of carbon negative carpet tiles.

Graphene technology is being used in paint to absorb carbon dioxide after its application.

A range of start-ups are producing boards from wood waste, storing the carbon that would usually occur from burning or landfilling. The panels also act as an insulator and contribute to improved operational efficiency. Examples include Adaptavate and Baux acoustic panels.

For Operational Emissions, there are two solutions:

Energy Efficiency

The current challenges in energy security and energy prices have intersected with the climate crisis to remind us that energy efficiency is more important than ever.

The International Energy Authority now refers to energy efficiency as the “first fuel” and points out that without action on efficiency, the transition to Net Zero will be more expensive and more difficult to achieve. Further information is available in the IEA’s report entitled The value of urgent action on energy efficiency.

Most energy efficiency measures are cost-effective and pay back through energy savings, although most require investment up-front.

See LETI’s guidance on net zero operational energy for more information.

Renewable Energy

Long popular for its visual badging, renewable energy on buildings includes solar photovoltaic panels and wind turbines. As these technologies grow in scale and grid prices increase, their economics continue to improve.

On-site generation of renewable energy reduces losses and reduces transmission infrastructure, however, renewable energy is also available from most energy suppliers – often at no greater cost than energy from fossil fuels.

Conclusions

Net Zero Carbon will affect all parts of the economy, especially buildings which, due to their prominence, measurability, and long cycles, are likely to be an early focus.

Net Zero Carbon buildings will require the widespread adoption of renewable energy, energy efficiency, the circular economy and carbon negative materials.

About Rype

As well as helping our customers to reduce their carbon emissions with remanufactured and recycled office furniture, we are on our own journey to Net Zero. As signatories to the SME Climate Commitment, recognised by the United Nations Race to Zero, we have committed to halve our GHG emissions before 2030, achieve Net Zero before 2050 and disclose our progress on a yearly basis.

References:

[1] IPCC, 2018: Chapter 2 – Mitigation pathways compatible with 1.5°C in the context of sustainable development

[2] Source: https://www.carbontrust.com/what-we-do/net-zero, accessed 19 September 2020

[3] Source: Treloar, GJ. Et al, 1999, Embodied energy analysis of fixtures, fittings and furniture in office buildings, Facilities, Volume 17, Number 11, pp. 403-409 (Accessed on 14 June 2019 at https://www.academia.edu/18481731/Embodied_energy_analysis_of_fixtures_fittings_and_furniture_in_office_buildings)

[4] Source: https://www.carbontrust.com/resources/briefing-what-are-scope-3-emissions accessed on 19 September 2020.