How will products change as carbon emissions are reduced? This discussion illustrates how the Circular Economy will challenge the Linear Economy, using the example of the office furniture sector.

Carbon Emissions Reduction Targets

Organisations committed to Net Zero Carbon by 2050 must reduce their greenhouse gas emissions by 50% before 2030 and by 90 to 95% before 2050, as prescribed in the Science Based Targets Initiative’s Net Zero Corporate Standard.

In previous articles, including How to Write a Net Zero Transition Plan, the size and importance of embodied emissions (those emissions that go into the making of products) has been recognised.

So how will organisations hit these targets for embodied emissions? This will vary by industry and will be influenced by the actions of customers, suppliers and intermediaries. Below is how Rype believes change will occur in the office furniture sector, responsible for 30% of a commercial building’s lifetime carbon emissions[1].

The Furniture Choices Available

Clients and specifiers have three office furniture sources to choose between:

1. New furniture

This is the most expensive furniture source, both financially and environmentally, due to long global supply chains and the consumption of raw materials and energy during production and transport.

With linear business models and highly centralised production, new furniture manufacturers have only one avenue available to reduce their products’ emissions: recycled content.

Unfortunately, recycled content only has a limited impact on emissions. While the carbon emissions of the raw materials can be significantly reduced by recycling (for example, recycling steel reduces greenhouse gas emissions by 73%[2]), the emissions to shape, trim, polish/surface coat and transport steel remain significant. Rype estimates the net carbon emissions reduction for furniture made from 100% recycled materials to be in the range of 50% to 60%.

Note that 100% recycled content remains a distant hope for manufacturers. Humanscale’s Path chair, which Humanscale claims to be “the world’s most sustainable task chair” has just 53% recycled content[3]. Herman Miller has a 2030 target of 50% recycled content for its iconic Aeron chair[4].

Assuming a 2030 best case recycled content of 50% across all furniture and a 60% reduction of emissions from the recycled content, the net impact is a 30% (i.e. 50% of 60%) carbon emissions saving. This falls well short of the 2030 target of a 50% reduction.

2. Second hand furniture

By contrast, second hand furniture (unrefurbished) has a very low carbon emissions footprint, thanks to environmental impacts resetting to zero at the end of its first life. Carbon emissions for reused second hand furniture is therefore limited to the transport emissions and any cleaning done.

Second hand furniture is also much lower cost than new.

However, because second hand furniture has no refurbishment or remanufacturing done to it, its quality is entirely dependent on the robustness of its original manufacture and the treatment that it has received in use and handling.

Further, second hand furniture can be difficult to integrate into a new design due to the original colours and sizes (for example, 1.8m x 1.2m beech return desks designed for cathode ray tube monitors).

3. Remanufactured/refurbished furniture

Remanufacturing transforms used office furniture back to as-new condition, in the preferred colours and sizes for a design scheme. It also represents good value-for-money, costing around 20% to 30% less than the same furniture made new. And it is done locally, generating local employment and avoiding international supply chain issues and delays.

Remanufacturing has been found to reduce carbon emissions by 80%[5]. Rype expects this percentage to increase over time as technology improves and new furniture is chosen for its remanufacturability.

Refurbishment, because it requires less work than remanufacturing, has an even greater carbon emissions saving – although it may not provide the finish required for a freshly refurbished office.

Focus on 2030

A 50% reduction in greenhouse gas emissions by 2030 is the immediate priority for those organisations with a Net Zero Carbon commitment.

It is reasonable to expect that new furniture manufacturers will advertise the recycled content of their products, as well as the source of that recyclate, such as ocean plastic.

Humanscale’s claim that its Path chair is “the world’s most sustainable task chair” is an example of such communications, noting that this claim ignores the greater sustainability of remanufactured and upcycled chairs like the Rype Zero, and therefore exposes Humanscale to claims of greenwashing.

Given the marketing budgets, client and specifier relationships, and established brands of manufacturers, it is logical that their recycled content furniture will take market share from new furniture made from virgin resources, despite falling short of the 50% carbon emissions reduction target. Given that clients and specifiers are inexperienced with carbon reduction, it is expected that greenwashing will sell many products.

In parallel, it is expected that remanufactured/refurbished furniture will grow market share at approximately the same rate as furniture with recycled content. Despite greater environmental benefits, social value creation and value-for-money, the remanufactured furniture category is new to many customers and specifiers.

Some organisations may not engage with climate change in any meaningful way and therefore furniture made from virgin resources is anticipated to continue to dominate the market in 2030.

Second hand furniture is expected to maintain its 10% market share due to its quality not meeting the standards required for a new or newly refurbished office.

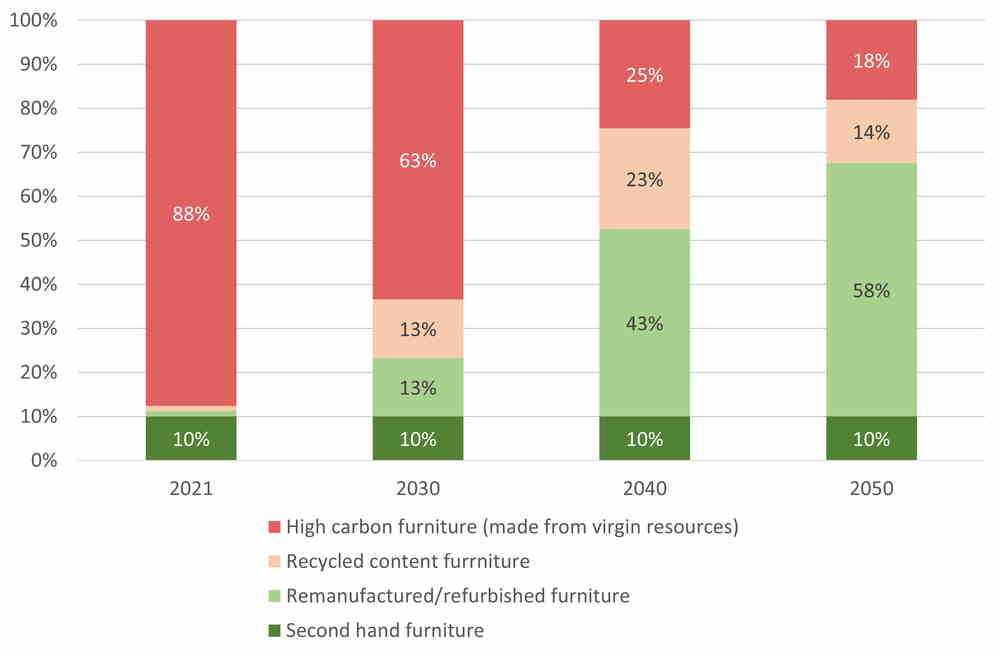

Figure 1 shows how Rype expects these developments shape the office furniture market by 2030.

Figure 1: Market share of office furniture categories

From 2030 to 2050

Given the milestone that 2030 represents for emissions reduction, it is expected that carbon reduction achievements in 2030 will be examined in detail by the media, consumer groups, environmental groups and government. This should highlight missed targets and force organisations to challenge their assumptions, which will expose greenwashing from suppliers.

Organisations will be focussed on substantial reductions in emissions towards the 90% to 95% target for 2050 and wary of the false claims and inadequate emissions reductions through recycled content.

It is therefore reasonable to anticipate that remanufactured furniture will take market share from both furniture made from virgin resources and recycled content, although the latter will likely remain in the consideration set, supported by the large marketing budgets of manufacturers.

The demand growth for remanufactured furniture will be assisted by organisations planning for multiple lives of their furniture for carbon emissions reduction to 2050 and the large cost savings from doing so.

Of course, not all organisations will engage with climate change by 2050 and therefore it is reasonable to expect around 20% of furniture sold to still be made from virgin resources.

This transition is shown in the latter columns of Figure 1.

Conclusion

Carbon emissions reduction is expected to significantly change most product sectors. For office furniture, remanufactured/refurbished items are expected to dominate the market by 2050, representing a significant change for the industry that will bring co-benefits of reduced costs for customers and local jobs.

About the Authors

Rype Office is a leading office furniture remanufacturer based in the UK. Phone: 033 3358 3330 or email contact@rypeoffice.com

References

[1] Source: Treloar, GJ. Et al, 1999, Embodied energy analysis of fixtures, fittings and furniture in office buildings, Facilities, Volume 17, Number 11, pp. 403-409 (Accessed on 14 June 2019 at https://www.academia.edu/18481731/Embodied_energy_analysis_of_fixtures_fittings_and_furniture_in_office_buildings)

[2] Source: https://link.springer.com/article/10.1007/s11367-016-1081-1

[3] Source: https://www.humanscale.com/products/seating/path-task-office-chair

[4] Source: https://www.hermanmiller.com/en_afr/press/press-releases/herman-miller-increases-use-of-ocean-bound-plastic-with-aeron-chair/

[5] Sources:

Giuntini, R., Gaudette, K. Remanufacturing: The next great opportunity for boosting US productivity, Business Horizons, Nov-Dec 2003, p. 44.

McKenna, R. President and CEO, Motor & Equipment Manufacturers Association, Testimony before the International Trade Commission on: Remanufactured Goods: An Overview of the U.S. and Global Industries, Markets, and Trade, Investigation No. 332-525, Feb 2012.